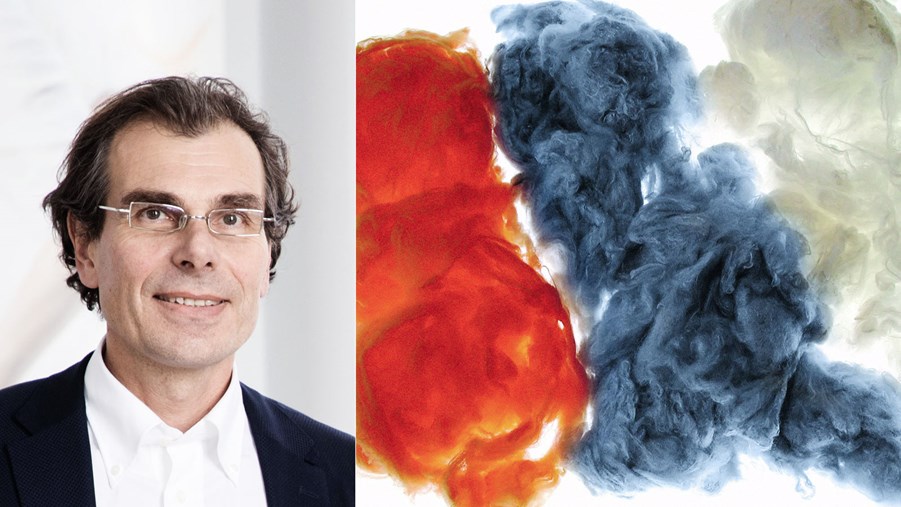

Peter Bartsch, Head of Corporate Sustainability at Lenzing, one of the world’s leading producers of environmentally compatible, wood-based cellulose fibres: viscose, modal and lyocell.

Why do you consider wood to be the best source for your cellulose fibre?

– Compared to other alternatives such as bamboo, cotton and straw, the large-scale production of cellulose in a sustainable and renewable way is best sourced from wood. Cotton production often competes with food production for limited land resources and poses other challenges as it requires a lot of water and pesticides. Alternatives such as bamboo and straw do not yet meet our needs in terms of availability and quality. So, if you look at the material as a whole, the best way to source high quality cellulose today is from sustainably managed forests.

The viscose industry is often criticised for having a negative impact on the environment due to its chemical intensive production. How is Lenzing different?

– We have developed technologies to make viscose production more environmentally friendly than before. Such technologies include efficient recovery systems, in which all the chemicals used in the production process are carefully managed, recovered and reused to achieve the lowest possible emissions to water and air.

Your lyocell-fibre production method is very innovative – fill us in...

– Our production process for Tencel- branded lyocell fibres requires only one solvent to dissolve the wood-based cellulose in a closed loop system. This is a mechanical dissolving process that does not require any additional chemicals. The recovery rate of the solvent is higher than 99%, which makes the process very resource efficient and sustainable.